Polyester chips are an essential raw material used in the production of polyester fibers, films, and plastics. These small, pellet-like forms of polyester serve as a building block for a wide range of consumer and industrial products, including textiles, packaging materials, and engineering plastics. Understanding polyester chips involves diving into their chemical composition, production process, applications, and significance in industries such as fashion, packaging, and electronics.

The Composition of Polyester Chips

Polyester chips are made from polyethylene terephthalate (PET), a polymer created through the polymerization of two main components: purified terephthalic acid (PTA) and ethylene glycol (EG). These two chemicals undergo a condensation polymerization reaction, resulting in a strong and durable polyester material. The polymerization process produces long chains of repeating ester groups, which give polyester its notable characteristics like durability, resistance to shrinking, and moisture-wicking properties.

Polyester chips may also include additives depending on the intended use, such as colorants, UV stabilizers, or flame retardants. These additions modify the properties of the polyester to meet specific industry needs.

The Production Process of Polyester Chips

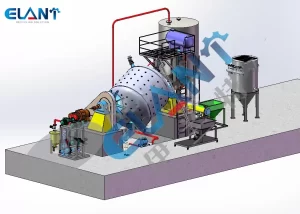

The process of producing polyester chips is complex and occurs in multiple stages, from raw material synthesis to final pelletization.

a. Polymerization

The first step in creating polyester chips is the polymerization process. In this step, PTA and EG are combined under controlled conditions of heat and pressure to form long molecular chains of polyester. This polymerization occurs in a reactor vessel, producing a highly viscous liquid.

b. Cooling and Pelletization

After polymerization, the molten polyester is extruded into thin strands and cooled using water or air. These strands are then cut into small pieces, which form the polyester chips. The cooling step is crucial, as it solidifies the polymer and prepares it for further processing.

c. Drying

Once the chips are formed, they undergo a drying process to reduce moisture content. Excess moisture in polyester chips can lead to defects during further processing, such as spinning or molding.

Types of Polyester Chips

There are different grades of polyester chips depending on their intended applications. The main types include:

a. Textile-Grade Polyester Chips

These polyester chips are primarily used in the production of fibers for textiles. The fibers made from textile-grade polyester chips are durable, resistant to stretching, and retain their shape well. This makes them popular in the production of clothing, upholstery, and other fabrics.

b. Bottle-Grade Polyester Chips

Bottle-grade polyester chips are specifically designed for making PET bottles and packaging materials. These chips are processed into a molten state and blown into molds to form lightweight, transparent, and recyclable bottles. PET bottles are widely used for beverages, cosmetics, and household products due to their strength and barrier properties.

c. Film-Grade Polyester Chips

Film-grade polyester chips are used to create polyester films, which have applications in packaging, electronics, and other industries. Polyester films offer high tensile strength, chemical resistance, and electrical insulation properties, making them useful in food packaging, magnetic tapes, and electrical insulations.

Applications of Polyester Chips

Polyester chips are versatile and find applications across several industries. Some of the most common uses include:

a. Textile Industry

In the textile industry, polyester chips are melted down and spun into fibers that are then woven or knitted into fabrics. Polyester is known for its strength, durability, and resistance to wrinkles, making it ideal for use in clothing, home furnishings, and industrial fabrics.

b. Packaging Industry

Polyester chips play a significant role in the packaging industry, where they are used to manufacture PET bottles and containers. PET packaging is lightweight, durable, and recyclable, which makes it a popular choice for food and beverage packaging, pharmaceutical products, and personal care items.

c. Electronics and Electrical Components

Polyester chips are also used to produce films that serve as insulation materials in electronic devices. These polyester films provide high dielectric strength and resistance to moisture, making them essential components in capacitors, transformers, and other electronic devices.

d. Automotive Industry

In the automotive industry, polyester fibers and films are utilized for making seatbelts, upholstery, and interior trims. The durability and chemical resistance of polyester materials ensure they can withstand the wear and tear of automotive use.

Environmental Considerations of Polyester Chips

Polyester chips, particularly PET, have become an integral part of the modern economy, but their production and usage raise environmental concerns. PET is derived from non-renewable petroleum resources, and the production of polyester chips requires significant energy and generates emissions.

a. Recycling Polyester Chips

One of the primary solutions to address the environmental impact of polyester chips is recycling. Recycled polyester (rPET) is made from post-consumer PET bottles, packaging, or discarded polyester textiles. The recycling process involves collecting, cleaning, and reprocessing used materials into new polyester chips. The use of rPET reduces the demand for virgin polyester, conserves resources, and reduces the environmental footprint of polyester production.

b. Sustainability Efforts

To enhance the sustainability of polyester production, industries are investing in innovative processes such as chemical recycling and biobased alternatives. Chemical recycling involves breaking down polyester materials back into their monomers, which can then be re-polymerized into new polyester. Meanwhile, biobased polyester is made from renewable resources, such as plant-based materials, to reduce reliance on fossil fuels.

The Future of Polyester Chips

As industries continue to demand versatile, durable, and cost-effective materials, polyester chips are likely to remain a crucial component of various products. However, the shift towards sustainability and circular economy practices will drive innovations in polyester production, including the adoption of greener manufacturing processes and recycling technologies.

a. Emerging Trends

Innovations such as biodegradable polyesters, advanced recycling techniques, and bioplastics are emerging as potential solutions to the environmental challenges posed by polyester chips. These advancements are expected to play a significant role in reducing the environmental impact of polyester and promoting a more sustainable future.

Conclusion

Polyester chips are a fundamental material that powers many industries, from textiles and packaging to electronics and automotive applications. Understanding their composition, production processes, and diverse applications is crucial for appreciating the importance of polyester in modern life. While challenges like environmental impact exist, ongoing efforts in recycling and sustainable production methods offer promising solutions. As polyester technology evolves, it will continue to be a key material driving innovation and efficiency in multiple sectors.