- +86-18606286868 | +86-512-58138883

- sales@elantmachine.com

Our PP Woven bag recycling machine line is used to recycle waste plastics such as plastic bags, PP woven bags, plastic agriculture film, greenhouse films, mulching films, plastic package films, PE waste film, PP waste film, PVC waste film, industrial film, printed film and etc.

But each kind of plastic films will contain different pollutants so it requires different washing process and washing line will be different. So firstly, please confirm with us that which kind of plastic films you want to recycle.

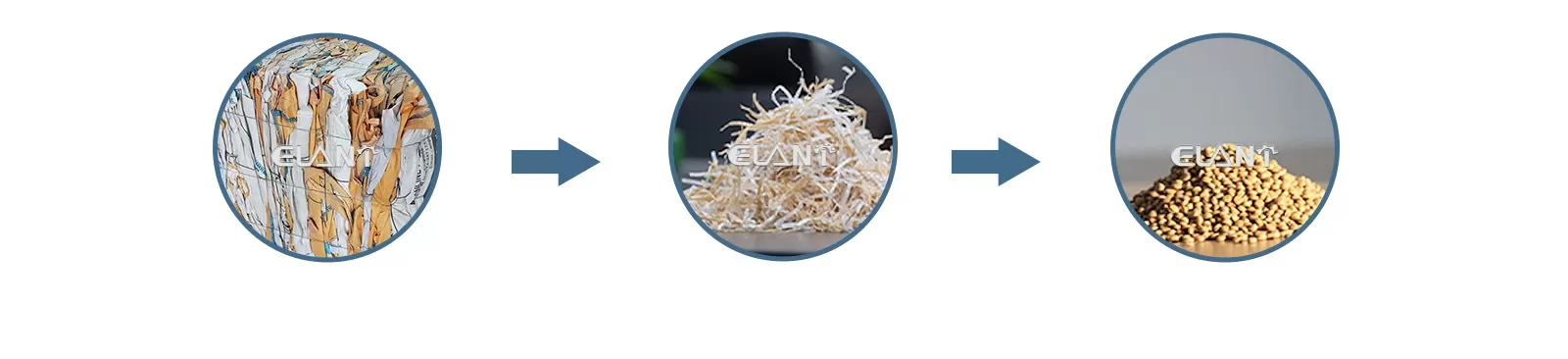

Recycling Process:

PP woven bags recycling machine mainly including the following machine system:

– Shredder system for reduction size of large baled woven bags or loosen jumbo bags.

– PP woven bag washing line to get clean crushed and dry PP flakes.

– PP pelletizing machine to make PP granules or pellets from PP flakes so then the material can be reused for plastic product production.

PP woven bag washing line is specially used for crushing, washing and drying PP woven bags and to get clean crushed dry PP film flakes from dirty PP woven bags.

This PP woven bag washing recycling machine line can automatically work, only need 3 to 4 people to operate easily. It is with high capacity, low energy consumption, effective design,etc.

Main models: | Capacity | Motor power | Workshop area | Water consumption |

EPP-500 | 500kg/hr | 150kw | 45*10*6m | 3-5ton/hr |

EPP-1000 | 1000kg/hr | 190kw | 70*12*6m | 8-10ton/hr |

Working Process Flow of PP woven bag washing line:

Belt conveyor→ crusher→ low speed friction washer → high speed friction washer→ floating washer→ screw loader→ horizontal friction machine → screw loader → floating washer →Friction washer → plastic squeezer dryer.

In order to improve capacity and quality of final product, we can adjust technological process according to the requirement of different materials.

Our PP woven bag crushing washing line is made of stainless steel SUS304 to guarantee the reliable performance. The main electrics are from international brands, such as Siemens, Schneider, ABB, Omron, et.

PP pelletizing machine combines function of crushing, compacting, plasticization and pelletizing to one step. applied in the soft plastics recycling and pelletizing process.

This granulator system is a reliable and efficiency solution for plastics films, raffias, filaments, bags, woven bags and foaming materials re-pelletizing.

Final productions produced by our granulator system are in the form of pellets/ granules, can directly put into the production line for film blowing, pipe extrusion and plastics injection, etc.

Application:

Applicable plastics material:

Material shapes: film, raffia, filament, woven bag and nonwoven fabric and other consumed / post soft or rigid plastic.

Note: Depending on material property, various downstream equipment are available.

PP pelletizing Machine Process Flow:

No. | Name | Qty. |

1 | Belt conveyor & metal detector | 1set |

2 | Compactor | 1set |

3 | Single screw extruder(one stage or double stage) | 1set |

4 | Hydraulic screen changer | 1set |

5 | Plastic pelletizing system(water-ring cutting system or strand pulls cutting system) | 1set |

6 | Dewatering machine | 1set |

7 | Air transmission and silo storage | 1set |

Model | ECS85 | ECS100 | ECS130 | ECS160 | ECS180 | |

Output | PP | 120KG | 250KG | 400KG | 600KG | 800KG |

HDPE | 150KG | 300KG | 500KG | 700KG | 1000KG | |

LDPE | 180KG | 400KG | 600KG | 800KG | 1200KG | |

Machine weight | 4000KG | 6000KG | 8000KG | 12000KG | 15000KG | |

Total power | 140KW | 215KW | 325KW | 420KW | 590KW | |