- +86-18606286868 | +86-512-58138883

- sales@elantmachine.com

Plastic Film Recycling machine Line is used to recycle and reprocess waste plastic materials like LDPE agriculture film, LLDPE stretch film, PP woven bag, PP jumbo big bag etc. Plastic Film Recycling machine can efficiently clean and remove the soil, sand, stone, glue, grass, oil, paper sticker and other dirt on the agricultural film.

We can also customize the production line and machines for waste plastic film recycling plant according to how dirty of plastic films and other special requirements.

The input capacity of our standard plastic film recycling machine ranges from 500kg/h to 1,500kg/h.

In terms of output capacity, this is heavily dependent on the amount of contamination within the PP / PE plastic films you’re recycling. While most washing plants operate perfectly well using just our standard set of machinery, we also offer custom solutions to recyclers that require larger capacities or the separation of various contaminants not removed using our standard washing lines.

The Plastic Film Recycling Machine Plant mainly including:

Application:

Our plastic film washing machine line is used to recycle waste plastic such as plastic bags, PP woven bags, plastic agriculture film, greenhouse films, mulching films, plastic package films, PE waste film, PP waste film, PVC waste film, industrial film, printed film and etc.

But each kind of plastic films will contain different pollutants so it requires different washing process and washing line will be different. So firstly, please confirm with us that which kind of plastic films you want to recycle.

The types of plastic films commonly found in the recycling market are:

Main models: | Capacity | Motor power | Workshop area | Water consumption |

EPE-500 | 500kg/hr | 150kw | 45*10*6m | 3-5ton/hr |

EPE-1000 | 1000kg/hr | 190kw | 70*12*6m | 8-10ton/hr |

EPE-1500 | 1500kg/hr | 250kw | 75*15*6m | 10-15ton/hr |

Above date is only for reference. We can design the plastic film washing line according to different material grade and different requests and above date will be different.

Working Process Flow:

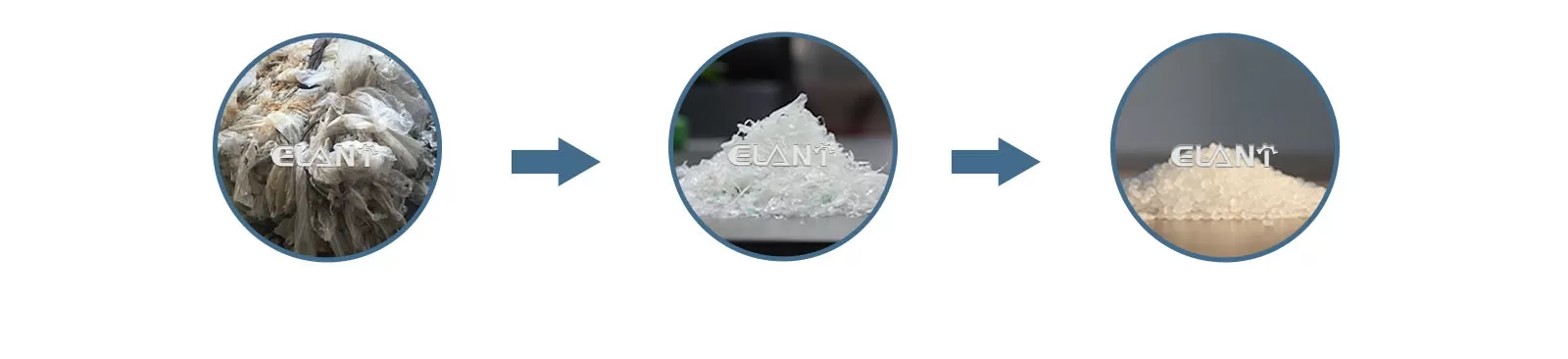

Plastic Sorting→ Shredding→ Crushing→ High-Speed Friction washing→ Floating Washing→ Drying- Packaging for Plastic Washing Recycling Machine for Sale

Cleaning Process

*Metal detector and crusher as a group to cut the film into small and avoid harm to knife in crusher.

*Floating wash tank for pre-wash LLDPE film.

*Label remover system to separate film and stickers especially for LLDPE packaging film.

* Film squeezing machine efficiency. Equipped with conical film squeezing machine on drying section, we can promise the humidity of final LLDPE film less than5%. LLDPE film after processing by our film washing line and then it could send to next our series LLDPE film

pelletizing recycling machine for making granulation.

*Easy operation with low power consumption.

Application material

PVC, PE, PP, ABS, PA, BOPP, CPP, HDPE, LDPE, LLDPE, PET, EPE, PS, ABS, OPP, Caco3 etc.

Material shapes: All kinds of plastic material, such as fiber, tube, profile, woven bag, printed LDPE film, film (rolls, loose, bundled), agricultural film waste, foamed plastics (EPE), bottle and raffia etc.

Note: Depending on material property, various downstream equipment are available.

Features:

This series plastic recycling granulator machine have high effectively exhausting, filter, screen changer.

Material is cut, pre-dried, pre-heated, pre-homogenized and compacted in the shredding drum.

Many materials can be processed directly without need of the upstream pre-shredding, resulting in a dramatic reduction in operational costs.

Less power consumption cost per kilogram, high throughput,reduced floor space occupation and operator attendance.

Model | ECS85 | ECS100 | ECS130 | ECS160 | ECS180 | |||

Output | PP | 120KG | 250KG | 400KG | 600KG | 800KG | ||

HDPE | 150KG | 300KG | 500KG | 700KG | 1000KG | |||

LDPE | 180KG | 400KG | 600KG | 800KG | 1200KG | |||

Machine weight | 4000KG | 6000KG | 8000KG | 12000KG | 15000KG | |||

Total power | 140KW | 215KW | 325KW | 420KW | 590KW | |||

Compactor/agglomerator | Compactor diameter | φ800mm | φ1000mm | φ1200mm | φ1300mm | φ1500mm | ||

Blade(rotary/stable) | 6/5 | 6/12 | 9/12 | 9/13 | 12/15 | |||

Motor | 37KW | 55KW | 90KW | 110KW | 160KW | |||

Extruder | Type | The degassing zone is designed by properties of different material | ||||||

Screw diameter | φ85mm | φ100mm | φ130mm | φ160mm | φ180mm | |||

Motor power | 55KW | 90KW | 132KW | 185KW | 250KW | |||