- +86-18606286868 | +86-512-58138883

- sales@elantmachine.com

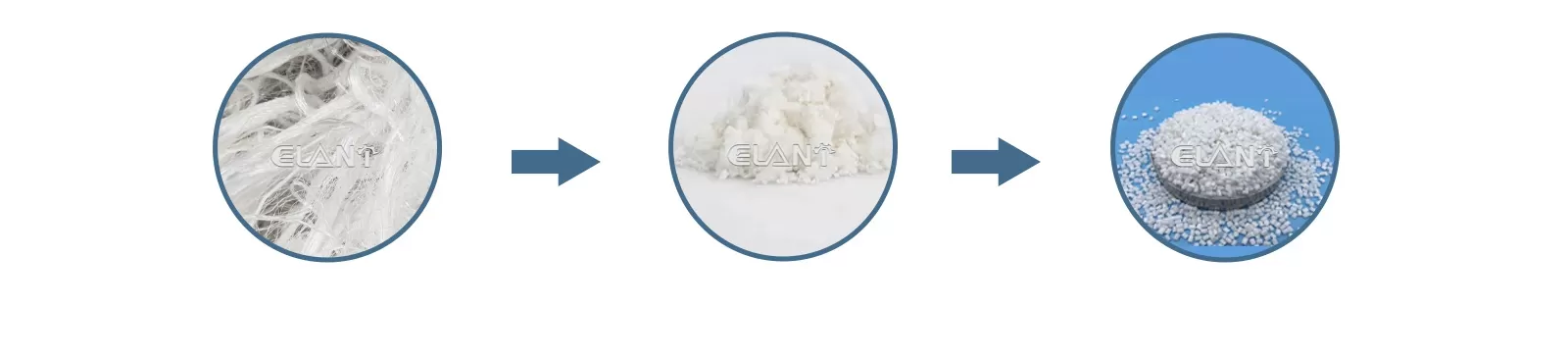

PET film fibers recycling machine including the shredder system and pelletizing line to get final PET granules or pellets.

The PET film fibers shredder machine is used to recycle plastic, paper, wood, fiber, cable, rubber, home appliance, light steel, municipal solid waste, etc. It is ideally suited for the reduction of a wide range of different materials as below:

Shredder model | ELS-3063 | ELS-3980 | ELS-48100 | ELS-57120 | ELS-75160 | ELS-80200 |

Shaft diameter(mm) | 300 | 340 | 400 | 400 | 500 | 500 |

Moving knife qty.(pcs) | 30 | 39 | 48 | 57 | 75 | 80 |

Fixed knife qty.(pcs) | 1 | 2 | 2 | 4 | 4 | 4 |

Max.capacity(kg/h) | 500 | 700 | 900 | 1500 | 5000 | 8000-10000 |

Motor power(kw) | 30 | 45 | 55 | 75 | 132 | 185 |

Hydraulic power (kw) | 4 | 5.5 | 5.5 | 7.5 | 11 | 15 |

Chamber size(L*W mm) | 780*670 | 1000*870 | 1200*1060 | 1400*1260 | 1800*1650 | 2200*2050 |

Host weight(kg) | 4000 | 6000 | 8000 | 9500 | 12000 | 16000 |

The PET series compacting and granulating system combines function of crushing, compacting, plasticization and pelletizing to one step. applied in the plastics recycling and pelletizing process. ECS system is a reliable and efficiency solution for plastics films, raffias, filaments, bags, woven bags and foaming materials re-pelletizing.

After the plastic melt is extruded through the porous casting die plate into strips, the strips are initially cooled by the moving water flow on the guiding trough (flume), and then is pulled into the pelletizing chamber, and then the strip is cut into pellets by the rotating pelletizing knives. After the water is further cooled, it is transported into the centrifugal dehydrator. After being dried by the centrifugal dehydrator, it enters the vibrating screen for screening, and finally qualified granules are obtained.

This process is full automatically, save labor cost and stable production and high output.

Technology Parameter | ||||||

Type | ECS80 | ECS100 | ECS120 | ECS140 | ECS160 | ECS180 |

Capacity (kg/h) | 150-250 | 300-420 | 400-600 | 600-750 | 800-950 | 1000-1200 |