- +86-18606286868 | +86-512-58138883

- sales@elantmachine.com

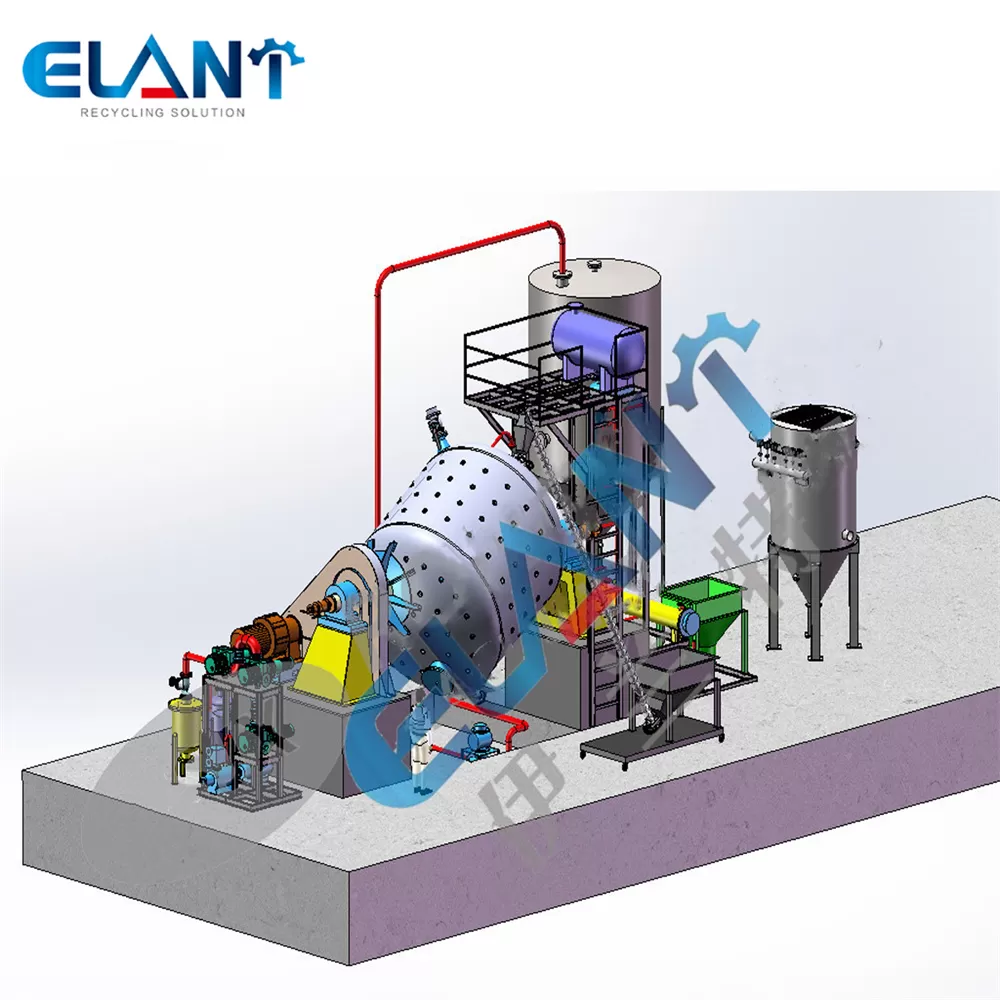

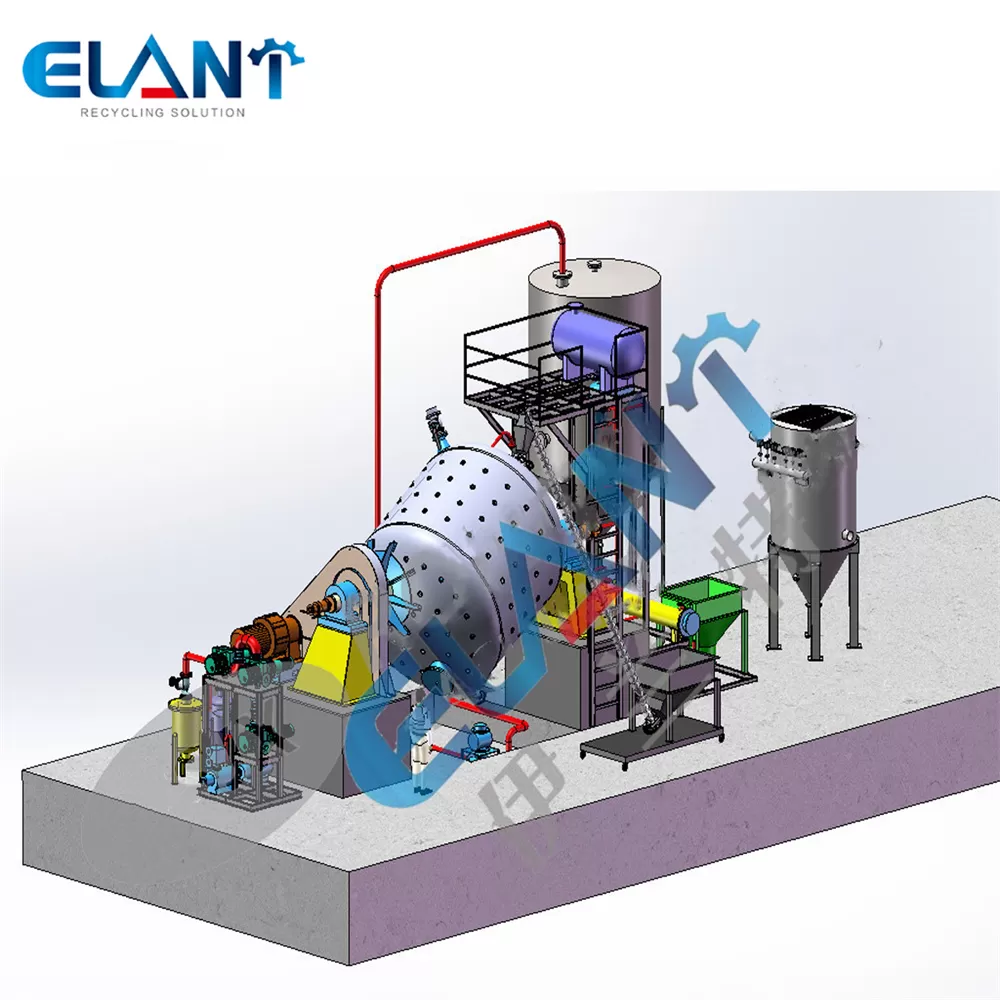

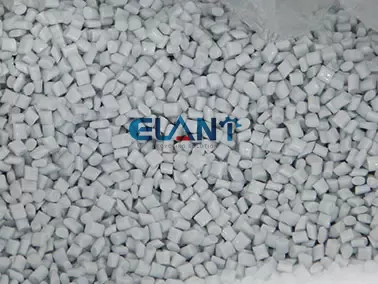

The Solid State Polymerization SSP system refers to the condensation polymerization reaction of solid chips, aiming to increase the molecular weight and intrinsic viscosity (IV).

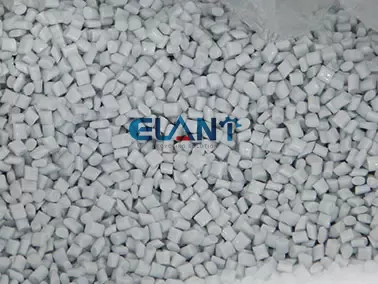

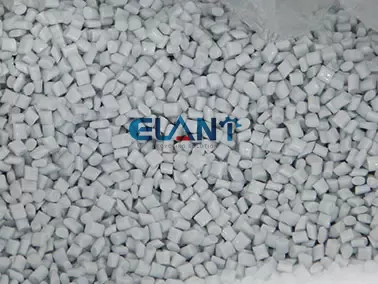

The normal PET Chips are heated to the glass transition temperature (usually 10-40 ° C below the melting point). The small molecular products are taken away by vacuum or inert gas protection (generally using high-purity nitrogen), so the polycondensation reaction is continued and the viscosity is further increased. End Carboxyl (COOH) content can be decreased when IV content is increased. This process can be used to produce various bottle-grade polyester, industrial filament-grade, low-end group content PET chips, etc. SSP can be classified as continuous or batch SSP according to the process.

Can increase: chip for virgin PET, recycled PET, PA6, PA66, PTT, PBT, PPS, PPL, PP and PE.

Application: Chemical fiber industrial filament, BCF, PET bottle and packaging, Special monofilament or Composite fiber, Special staple fiber, Non-woven fabrics, BOPET, Engineering plastics, etc.

According to the needs of consumers’ research, ELANT can supply integrated SSP pilot plant. It can be easily used when power is on.

Batch SSP system capacity: 5kg-20 tons/batch, with flexible product adjustment and Suitable for small-batch production.

Intrinsic viscosity(I.V):(According to specific raw material) PET I.V: Max.1.2

Energy consumption per ton for reference:200KWh/t~400KWh/t

(In accordance with capacity and I.V requirement)

Our Elant company has rich experience with more than 20years in manufacturing this Solid State Polymerization system, and we have installed many sample plants to our customers, some old customers even purchased 4sets-6sets in 25m3 SSP dryer from us, and they are very big factory for manufacturing PET films, PET bottles and Chemical fiber industrial filament.

Looking forward to your cooperation!

– What kind of plastic do you process?

– What’s the production output do you need per batch or per day?

– What’s the IV and your original material?

– And what IV do you want to increase after SSP system?