- +86-18606286868 | +86-512-58138883

- sales@elantmachine.com

1. De-Bale:

For debale the baled PET bottles or HDPE/PP bottles or other rigid plastics.

PET bottle recycling machine is mainly used to recycling the waste PET bottles, water bottles, cola bottles, PET sheet and PET packing containers. The PET Recycle Line can easily remove the labels, caps, rings, glue, dirties and other impurities, finally you will get ideal PET flakes. All your requirements of the PET bottle washing machine will be customized.

Our PET washing line is high automatic operating and save labor cost and low after maintenance. With advanced international industry concepts and technologies to meet waste plastic recycling at home or abroad.

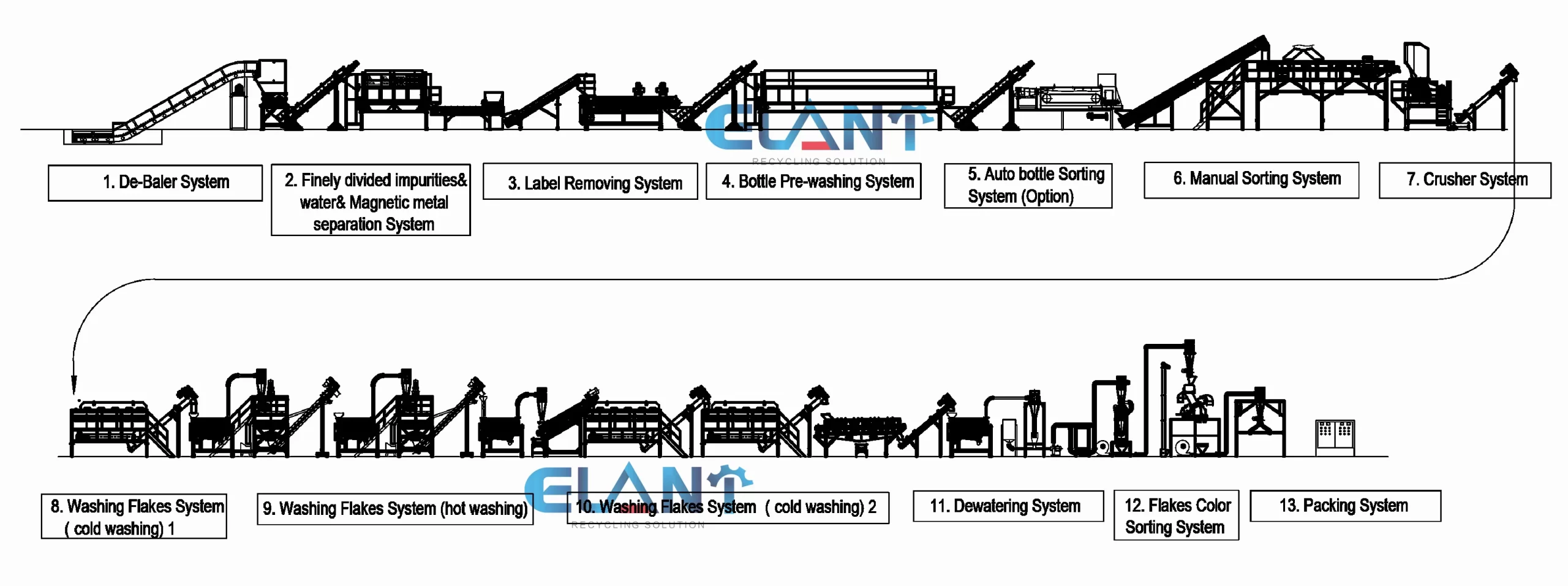

Feeding & debaler – Dry separation – Delabler – Hot/cold pre-washer –Automatic and manual sorting – Wet grinding – Hot washer – Sink/float separation – Rinsing- Drying – Fines separation – Flakes color sorting – Non-ferrous metals separator- Blending – Storage and Packaging etc.

Machine list of PET bottle washing machine:

| Machine List | |||||

| 1.0 | Metal chain conveyor

(sink into ground) |

8.0 | Steel platform | 15.0 | High speed dewatering machine |

| 2.0 | Bale breaker | 9.0 | Manual sorting table | 16.0 | Two way screw conveyor |

| 3.0 | Double screw loader | 10.0 | Metal detector and automatic separation device | 17.0 | Hot washer |

| 4.0 | Trommel machine | 11.0 | Crusher machine | 18.0 | High speed friction washer |

| 5.0 | Belt conveyor with metal detector | 12.0 | Horizontal screw feeder | 19.0 | Zig zag label aspiration machine |

| 6.0 | Label remover machine | 13.0 | Elevated screw feeder | 20.0 | Silo |

| 7.0 | Bottle pre-washer as optional | 14.0 | Floating washer | 21.0 | Electric control cabinet |

The complete set of washing process can also be adjusted as per customers detail requests, such as what grade of flakes quality and customer’s budget price on this plant.

Welcome to inquire us for more detail information.

| No. | Model/ Production capacity (Kg/hr) | Total installation power (Kw) | Water consumption (m3/hr) | Line size (mm): | Workers |

| 1 | 300-500kg/hr | 198 (adjustable) | 3-5 | 45*5*5 | 3-6 |

| 2 | 1000-1500kg/hr | 415 (adjustable) | 5-8 | 75*6*5m | 6-10 |

| 3 | 2000kg/hr | 603 (adjustable) | 8-12 | 106*6*5.8m | 10-12 |

| 4 | 3000kg/hr | 721 (adjustable) | 12-15 | 132*7*6.5m | 16-20 |

| 5 | 4000kg/hr | 966 (adjustable) | 15-20 | 150*7*7m | 16-20 |

Above date is only for reference. We can design the PET bottle washing line according to different material grade and different requests and above date will be different.

PET Flakes Quality Reference Table from PET bottle washing line:

| Item. | Description | Result | |

| 1 | Grade: | Recycled flakes, hot washed by Steam 80-90degree | |

| 2 | Color: | 100% clear, white, Blue/Green | |

| 3 | Intrinsic Viscosity (IV) (dl/g) | 0.65-0.76 (depends on raw materials) | |

| 4 | Melt point (℃) | 252-260 | |

| 5 | Moisture | 0.5-2% | |

| 6 | Bulk density (kg/m3) | 280-450 | |

| 7 | Particle size (mm) | 3-14 | |

| 8 | Fraction | 1-3mm | 8-15% |

| ≤1mm | Max. 2% | ||

| 9 | PH Value | Max. 9 | |

| 10 | PVC (ppm) | Depending on PVC sorter machine | |

| 11 | PE/PP (ppm) | Max. 50 (Need polymer sorter machine) | |

| 12 | Paper (ppm) | Max. 10 | |

| 13 | Glue (ppm) | Max. 10 (Need hot washer) | |

| 14 | Metal (ppm) | Max. 10 (Depending on ferrous metal and non-ferrous metal sorter machine) | |

| 15 | Other organics (ppm) | Max. 100 | |

For debale the baled PET bottles or HDPE/PP bottles or other rigid plastics.

To separate the rack contamination things, like stone, dirt, bottle caps, rings, etc.

To remove the labels which are just covered on bottles and sealed on one side by hot shrinkage air.

To separate the foreign materials manually and sort out different colors of bottles.

Crush and reduce the size of PET bottles into flakes of 15mm (two crusher are working in parallel, when one crusher has to stop for maintenance, another crusher can be still working to keep whole line non-stop.)

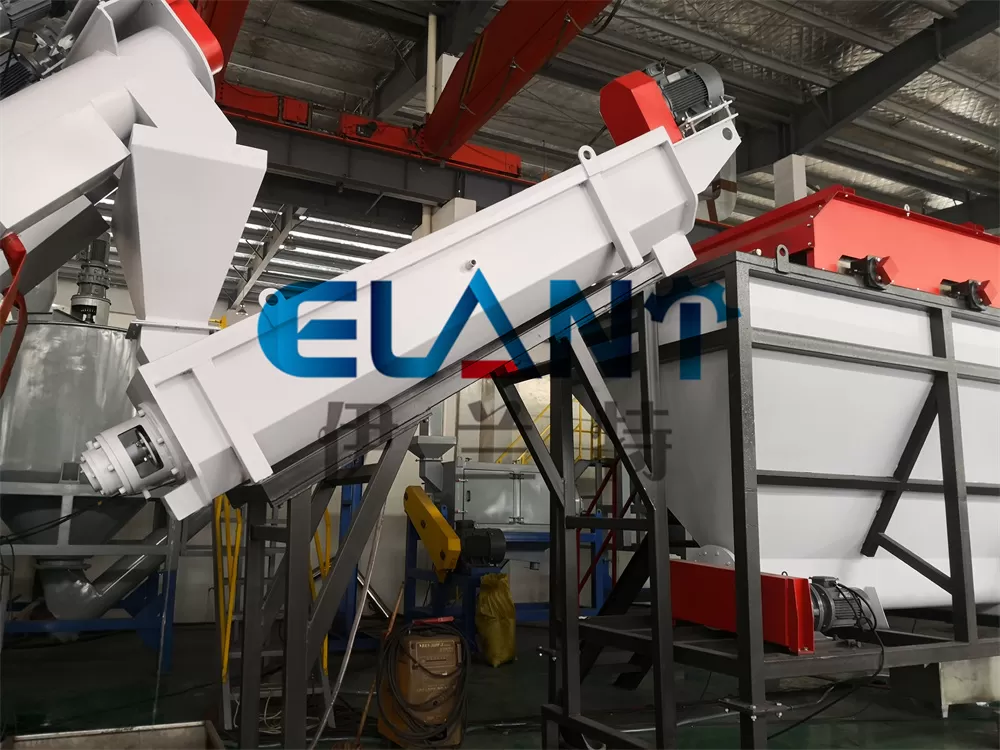

For washing PET flakes and separation of the labels and caps.

Clean the materials in hot water, with some chemical detergent or Caustic soda to reduce glue and oil.

Transport material to the next process for washing PET flakes.

Special blade arrangement, uniform discharge, sufficient friction cleaning, high water utilization rate, effective removal of paper labels and other impurities.

Separation ensures label separation rate >99.5%, powder <1%. Unique “Zig zag” structure design with dust filter.

Specially designed suction fan power controlling system

The material outlet is equipped with a magnetic rack (as an option) to remove tiny magnetic metal.

– What capacity do you need for PET bottle washing line?

– What’s the source of waste PET bottle are collected from?

– What’s the final usage of the end PET flakes? It means what quality grade of PET flakes will need.