- +86-18606286868 | +86-512-58138883

- sales@elantmachine.com

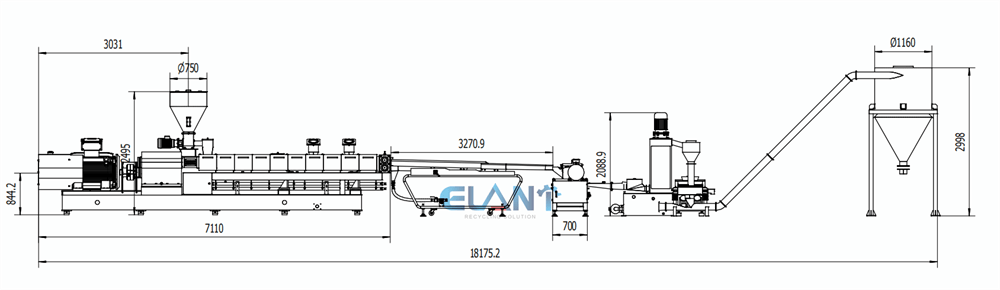

1. Parallel Twin screw extruder

Main motor: Imported “WEG” or “Siemens” variable frequency motor.

Adopting multi-stage vacuum exhaust port, when processing PET material, the material starts to dewater under extreme vacuum before it is completely melted, adopting enlarged opening cylinder and multi-stage vacuum exhaust to ensure the performance of the material;