- +86-18606286868 | +86-512-58138883

- sales@elantmachine.com

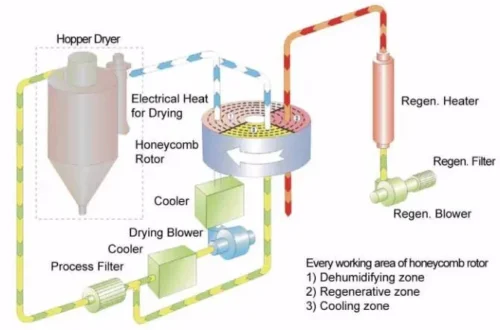

1. What is honeycomb rotor?

The main part of honeycomb rotor is made by ceramic fiber and organic additives, sintered under high temperature with molecular sieve or silica gel as basic material to bond together with inside of honeycomb to form the honeycomb-like structure.

Unlike common dessicant or rotary molecular sieve, then, when aging, will produce dust, followed by process air to drying hopper, to pollute plastic material. Honeycle rotor offers unlimited long service life and can be cleaned and not like usual dessicant which is easy to get saturated or requiring regular replacement.

The moisture of return air is quickly absorbed by molecular sieves when passing through numerous holes within honeycomb rotor. So when coming out of rotor, can form low dew-point dry air. Regenerating and dehumidifying have similar principle and run simultaneously. The only difference is that the two process winds are in opposite direction.