- +86-18606286868 | +86-512-58138883

- sales@elantmachine.com

In the production of polymers, the underwater pelletizer system is the latest granulation form, which is the ultimate solution for the inability to complete pelletizing, such as hot cutter pelleting system and water ring pelleting system.

ELANT has the most experienced R&D team of domestic underwater pelletizing systems, fully absorbing the latest advanced technologies of underwater pelletizing at home and abroad.

Classic application:

– Elastomer (TPU/TPE/TPV/SBS/SEBS, etc.)

– Hot melt adhesive (PES/PA/EVA, etc.)

– Degradable plastics (PBS/PLA, etc.)

– Color masterbatch (PE masterbatch / PP masterbatch / TPU masterbatch)

Micro particle size: 0.7-1.5mm

Thermoplastic Elastomer TPE, TPU, TPV, TPR,TPS, POE, EVA, SBS etc. are widely used in daily life, such as tpu fabric, tpu medical gloves, tpu phone case, tpu shoe sole, tpu strap, tpv sealing and others.

Due to its stickiness nature, hot glue is hard to cutting in traditional way, such as water-strand pelletizing, water ring, air cooling hot cutting. Therefore Elant adopt an advanced new cutting method–underwater pelletizing system. With the underwater pelletizer, granules come out from die head and flow into water directly, which increases the cooling efficiency, and makes the granules shaped good.

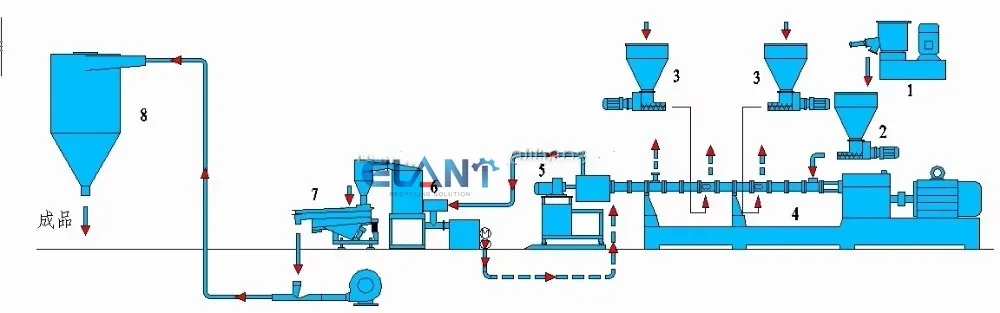

Drying hopper —–Low speed mixer —–Vacuum loader —–Granule gravimetric feeder—-Liquid gravimetric feeder —– Twin screw extruder ——Underwater pelletizer system —–Fluidizing bed with blower —–Dehumidifier —–Vacuum loader —– Vacuum packing machine —–Electric control cabinet

Technical specification of underwater plastic pelletizing machine:

| Mode | Diameter

(mm) |

L/D | speed

(r/min) |

Motor power

(kw) |

Torque

(N.m) |

Capacity

(kg/h) |

| TSE-20 | 22 | 32-44 | 600 | 5.5 | 43 | 0.5-10 |

| TSE-30B | 31 | 32-48 | 600 | 15 | 119 | 5-40 |

| TSH-35B | 35.6 | 32-52 | 600-800 | 15-22 | 119 | 30-70 |

| TSE-40B | 41 | 32-52 | 600 | 45-55 | 437 | 90-150 |

| TSH-40B | 41 | 32-52 | 600 | 45-55 | 437 | 150-220 |

| TSE-50B | 50.5 | 32-52 | 500 | 45-55 | 430 | 180-270 |

| TSH-52B | 51.5 | 32-60 | 600 | 90-132 | 682 | 270-400 |

| TSE-65B | 62.4 | 32-64 | 600 | 90 | 716 | 250-360 |

| TSH-65B | 62.4 | 32-64 | 600-800 | 110-160 | 875 | 350-500 |

| TSE-75B | 71 | 32-64 | 600 | 132 | 1050 | 350-500 |

| TSH-75B | 71 | 32-64 | 600-800 | 200-250 | 1365 | 600-800 |

| TSE-95B | 93 | 32-64 | 600 | 315 | 2560 | 800-1200 |

| TSH-95B | 93 | 32-64 | 600-800 | 400-450 | 2506 | 1200-1600 |

| TSE-135 | 133 | 32-64 | 500 | 550 | 7162 | 1500-2250 |

Would like to know more about ELANT Machine equipments, feel free to send us an inquiry!

Our Company Advantages:

We supply turn-key solutions to your compounding projects. This includes material handling, dosing, extrusion, pelletizing and

other aspects. Through our expertise you will find suitable solutions to your compounding system needs.

(1) Strictly selected brands: Main motor: Imported “WEG” or “SIEMENS” variable frequency motor, imported inverter(ABB or TOSHIBA)

(2) High output with low cost: output is 5-15% higher than the same model in the market.

(3) Advanced design: oil circuit, water circuit, vacuum and other pipeline are integrated designed with no need to install the pipeline separately, which can save 2 days on installation and $1000 from piping system.

(4) Certificate: CE, ISO:9001, TUV, 30+ patents

(5) Rich experience:

1) Engineers with 30+ years experience in plastic recycling pelletizing machine.

2) Exported to 60+ countries.

(6) Guaranteed after-sale service:

1) Whole extruder machine: 1 year warranty

2) Main gearbox: 3 years warranty

3) Overseas service provided.

– What kind of plastic material do you recycle? Are they new clean or dirty waste material?

– What’s the production capacity do you need for pelletizing machine?

– Please let us know as detail requests as possible.