- +86-18606286868 | +86-512-58138883

- sales@elantmachine.com

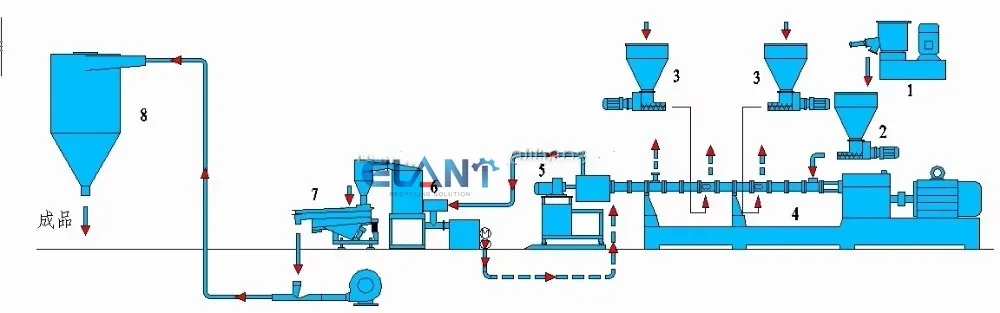

Water-ring die-face pelletizer line:

Application:

1.PE,EVA etc. ,filled with CaCO3, talc, TiO2, carbon black etc.

2.Cable sheath, cable insulation compounds of LDPE, HDPE, LLDPE, or MDPE;

3.PPR pipe compounds,PE compounds for crosslinked pipes;

4.TPR,TPU TPV thermoplastic elastomers; EVA and hot-melt adhesives

5.Color concentrates of PE,ABS,PS,EVA etc;

6.Flame retardant masterbatch of ABS,EVA etc;

7. Masterbatch with PE,PP,PS etc. As carriers for degradation applications.

Mainly including: 1. high-speed mixer 2. main feeder 3. side feeder 4. twin-screw extruder

5. water ring pelletizer 6. centrifugal off-water machinery 7. vibrating sieve

8. Silo

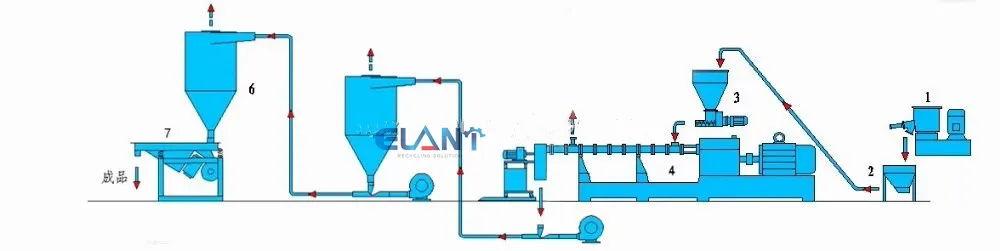

Air-cooling hot-face pelletizer:

Application :

Enforcing modification PE,EVA etc.+CaCO3 ,talc,TiO2,carbon black.

Degradable master batch:PE,PS etc. + starch,additive etc.

Anti-flame master batch :PE,EVA etc. +Sb2O3,Mg(OH)3 etc.

1. high-sped mixer 2. solids-conveyer 3. feeder 4. twin-screw extruder

5. air-cooling hot-face pelletizer 6.cyclone 7.vibrating sieve

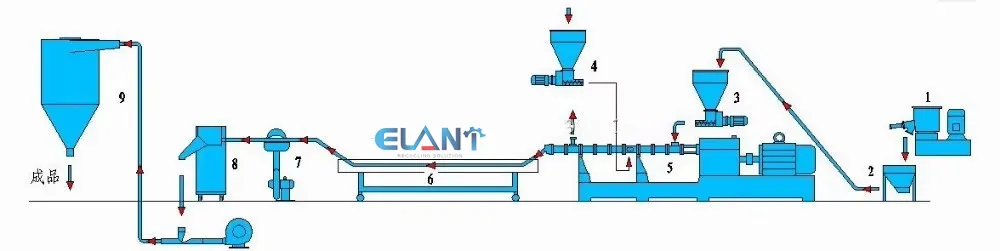

Water-cooling strands pelletizer:

Application:

1.Fiber reinforcement: glass fiber, carbon fiber reinforced PP,PA,PBT,ABS,AS,PC,POM,PPS,PET,PPO,PSF,LCP,etc.

2.Ploymer blending :bleding of PC+ABS, PA+ABS,CPE+ABS,PP+EPDM,PA+SBS,etc.

3.Incorporation of fillers :CaCO3,Tale,TiO2,carbon black filled PE,PP,or EVA etc.

4.Cable Compounds:cable sheath,cable insulation compounds of LDPE,HDPE,LLDPE,MDPE;radiation-crosslinkable compounds ,optical fiber protection compounds ,heat-shrinkable polymer compounds.

5.Special Compounds :PPR pipe compounds,PE compounds for crosslinked pipes,tobacco filter

compounds,etc

6.High Concentration Color Masterbatches: PE,ABS,PS,EVA,PET,PP etc. With high concentration of pigments and other procrssing aids.

7.Masterbatches with Flame Retardants:PP,PA,ABS,EVA,PBT etc.with flame retardants and other

additives.

8.Special Functional Masterbatches :Masterbatches with anti-static,anti-abcteria ,or other

special functional fillers.

9.Masterbatches for Degradable Polymers:PP,PE,PS etc. Blended with high concentration of starch and other processing aids.

1. high-sped mixer 2. solids-conveyer 3. main feeder 4. side feeder 5. side feeder

6. twin-screw extruder 7. water trough 8. air-knife 9. pelletizer 10. product container

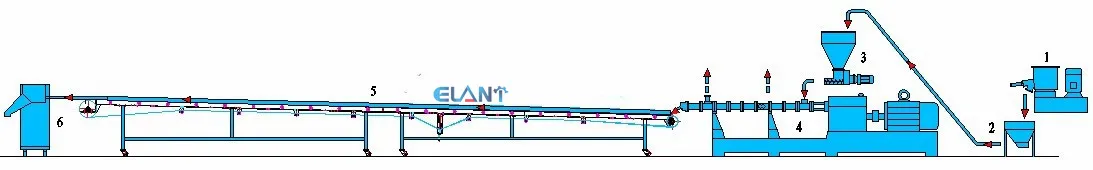

Air-cooling strands pelletizer system:

Application:

This Pelletizing extruder is used to the PP non woven Fabric masterbatch, PS Anti-flame masterbatch, Degradable masterbatch, etc.

1. high-sped mixer 2. solids-conveyer 3. main feeder 4. side feeder 5. belt conveyor

6. air-knife

TSE series co-rotating twin screw extrusion plastic pelletizing machine:

| Model | Screw diameter(mm) | Center distance(mm) | L/D | Screw speed(rpm) | Motor power(kw) | Screw torque(N.m) | Output(kg/hr) |

| TSE-52B | 51.4 | 43 | 36-44 | 500 | 55/75 | 420 | 155-280 |

| TSE-65B | 62.4 | 52 | 36-44 | 500 | 90/110 | 680 | 300-450 |

| TSE-75B | 71 | 60 | 36-44 | 500 | 132/160 | 1210 | 400-650 |

| TSE-95B | 93 | 78 | 36-44 | 500 | 280/315 | 2380 | 800-1200 |

| TSE-95D | 93 | 78 | 36-44 | 500 | 380/400 | 2680 | 1500-1700 |

Would like to know more about ELANT Machine equipments, feel free to send us an inquiry!

Elant’s TSE Series Co-rotating Parallel Twin-screw Extruder Features:

1. Screw components designed by computer aids is kneading type, has excellent self-cleaning function, the new kneading block

design effectively avoid the problems of overheating and energy consumption.

2. According to process system and formula requirements, the unit can optimize its L/D ratio, barrel structure, screw array,

venting number and location, feeding method, electrical control methods etc. for rational allocation.

3. Granulation system: water-cooling strand pelletizing, air-cooling die face hot cutting, water ring die face hot cutting,

water and underwater die face hot cutting and so on.

4. Application: Filling Modification, glass fiber (carbon fiber) enhance various kinds of master batch, rubber and plastics

compounding, plastic alloys, functional master batch, Various kinds of electric cable material, reactive extrusion.

Devolatilization process, powder coating and so on..

Our Company Advantages:

We supply turn-key solutions to your compounding projects. This includes material handling, dosing, extrusion, pelletizing and

other aspects. Through our expertise you will find suitable solutions to your compounding system needs.

(1) Strictly selected brands: Main motor: Imported “WEG” or “SIEMENS” variable frequency motor, imported inverter(ABB or TOSHIBA)

(2) High output with low cost: output is 5-15% higher than the same model in the market.

(3) Advanced design: oil circuit, water circuit, vacuum and other pipeline are integrated designed with no need to install the pipeline separately, which can save 2 days on installation and $1000 from piping system.

(4) Certificate: CE, ISO:9001, TUV, 30+ patents

(5) Rich experience:

1) Engineers with 30+ years experience in plastic recycling pelletizing machine.

2) Exported to 60+ countries.

(6) Guaranteed after-sale service:

1) Whole extruder machine: 1 year warranty

2) Main gearbox: 3 years warranty

3) Overseas service provided.

– What kind of plastic material do you recycle? Are they new clean or dirty waste material?

– What’s the production capacity do you need for pelletizing machine?

– Please let us know as detail requests as possible.