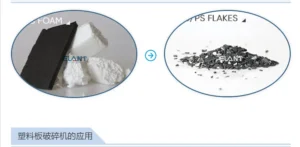

A plastic crusher machine is a crucial piece of equipment used in the plastic recycling industry to reduce the size of plastic waste. By crushing and grinding plastic materials, these machines make it easier to handle, transport, and further process plastic waste, contributing to more efficient recycling and waste management practices.

Components of a Plastic Crusher Machine

Blades or Rotors

- Material: Made from high-strength alloy steel or hardened stainless steel to ensure durability and resistance to wear.

- Design: Configured in various shapes and sizes, often with replaceable or adjustable blades to handle different types of plastics and optimize the crushing process.

Motor

- Power: Equipped with a high-torque motor to drive the blades or rotors, providing the necessary force to crush even the toughest plastics.

- Efficiency: Designed for energy efficiency to minimize operational costs and environmental impact.

Hopper

- Capacity: Varies in size to accommodate different volumes of plastic waste, from small batches to continuous feed systems.

- Design: Often includes safety features like interlocks to prevent accidental access to moving parts.

Output Screen

- Mesh Size: Comes with different mesh sizes to control the size of the crushed particles, ensuring uniform granulation according to the desired specifications.

- Replaceability: Easily replaceable to allow quick adjustments for different applications.

Frame and Casing

- Construction: Built from heavy-duty materials to withstand the mechanical stresses of crushing operations.

- Protection: Encloses the internal components to protect them from debris and dust, enhancing the machine’s longevity.

Control System

- Automation: Advanced models come with programmable logic controllers (PLCs) for automated operation, enhancing efficiency and safety.

- Safety Features: Includes emergency stop buttons, overload protection, and safety guards to prevent accidents and ensure safe operation.

Functions

Size Reduction

- Breaks down large plastic items such as bottles, containers, pipes, films, and other plastic products into smaller, more manageable pieces.

- Facilitates further processing like washing, melting, and re-molding in recycling operations.

Recycling Preparation

- Prepares plastic waste for subsequent recycling processes by reducing its volume, making it easier to clean, sort, and reprocess.

- Enhances the efficiency of recycling operations by providing uniformly sized plastic particles.

Waste Management

- Aids in the management and reduction of plastic waste, making transportation and disposal more efficient and cost-effective.

- Contributes to environmental sustainability by promoting the reuse and recycling of plastic materials.

Resource Recovery

- Enables the recovery of valuable plastic materials from waste, which can be reused to manufacture new products.

- Reduces the need for virgin plastic materials, conserving resources and reducing environmental impact.

Types of Plastic Crusher Machines

Single Shaft Shredder

- Features a single rotating shaft with cutting blades.

- Ideal for processing larger, tougher plastic materials like thick-walled pipes, blocks, and pallets.

- Provides efficient size reduction with controlled output particle sizes.

Double Shaft Shredder

- Equipped with two intermeshing rotating shafts with blades.

- Designed for heavy-duty applications, capable of handling mixed and contaminated plastic waste.

- Offers higher throughput and greater flexibility in processing different types of plastics.

Granulators

- Specifically designed for finer grinding and producing uniform granules.

- Often used in the final stages of the recycling process to produce high-quality recycled plastic granules.

- Available in various sizes and capacities to suit different production needs.

Applications

Plastic Recycling Plants

- Essential equipment for processing post-consumer and post-industrial plastic waste.

- Produces high-quality recycled plastic materials that can be used to manufacture new products.

Manufacturing Industries

- Helps manage and recycle plastic scrap generated during production processes.

- Reduces material waste and lowers production costs by enabling the reuse of recycled plastic.

Municipal Waste Management

- Used by waste management facilities to process plastic waste from households and businesses.

- Supports municipal recycling programs and contributes to reducing landfill waste.

Plastic Product Manufacturers

- Reprocesses defective products or production waste into usable material.

- Ensures efficient use of resources and minimizes production waste.

Agricultural Sector

- Processes agricultural plastic waste such as greenhouse films, irrigation pipes, and packaging materials.

- Contributes to sustainable farming practices by promoting the recycling of agricultural plastics.

Plastic crusher machines play a vital role in the recycling and waste management industries. By efficiently reducing the size of plastic waste, these machines facilitate the recycling process, contributing to environmental conservation and resource recovery. With advancements in technology, plastic crusher machines continue to evolve, offering improved performance, efficiency, and safety. As the demand for sustainable practices grows, the role of plastic crusher machines in recycling and waste management is expected to become even more significant, helping to address the global challenge of plastic pollution.